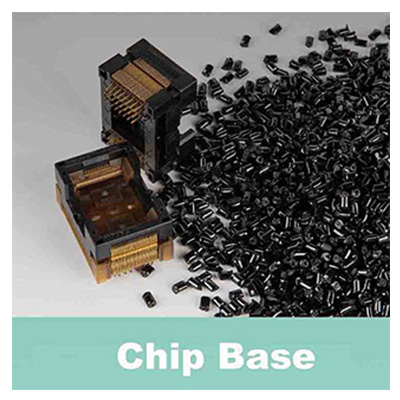

PES has good processing properties and is easily processed into various shaPES, making it suitable for making complex chip base designs. The geometry and structure of the base can be designed based on the functionality and requirements of the chip. Make sure that the size, hole positions, connection points, etc. of the base meet the layout and connection requirements of the chip.

PES is an electrically insulating material suitable for applications where the chip base needs to provide electrical isolation. Integrating the fabricated base with the chip ensures that the connection points are accurately matched for reliable electronic connection and functionality.

PES has high mechanical strength and hardness and can provide sufficient structural support. Suitable manufacturing processes, such as injection molding, machining, or 3D printing, can be used to produce PES chip bases that meet design specifications. The manufacturing process needs to ensure that PES materials are properly treated to maintain their characteristic properties.

PES is chosen as the material of the bottle. PES can maintain stability at relatively high temperatures and can resist overheated water temperatures that may cause the bottle to deform and break.

PES is chosen as the material of the bottle. PES can maintain stability at relatively high temperatures and can resist overheated water temperatures that may cause the bottle to deform and break.

PES is a relatively lightweight material that facilitates the design of lightweight bottles, taking the load off babies' arms so they can easily pick up the bottle. Sturdy and lightweight bottles also keep babies safe, preventing them from accidentally breaking the bottle and hurting themselves.

Based on data collection and analysis of the appeal of different bottles to babies, design a bottle with a size and shape that conforms to the baby's usage habits. Ensure that the design of the baby bottle meets the needs and quality and safety requirements of most customers.