There may be some specific design and process considerations when choosing to use polyethersulfone (PES) materials to make switch accessories.

Material selection: PES is a high-performance engineering plastic with high temperature stability, chemical stability and mechanical strength. Choose an appropriate grade and form of PES material, such as PES sheets or PES pellets.

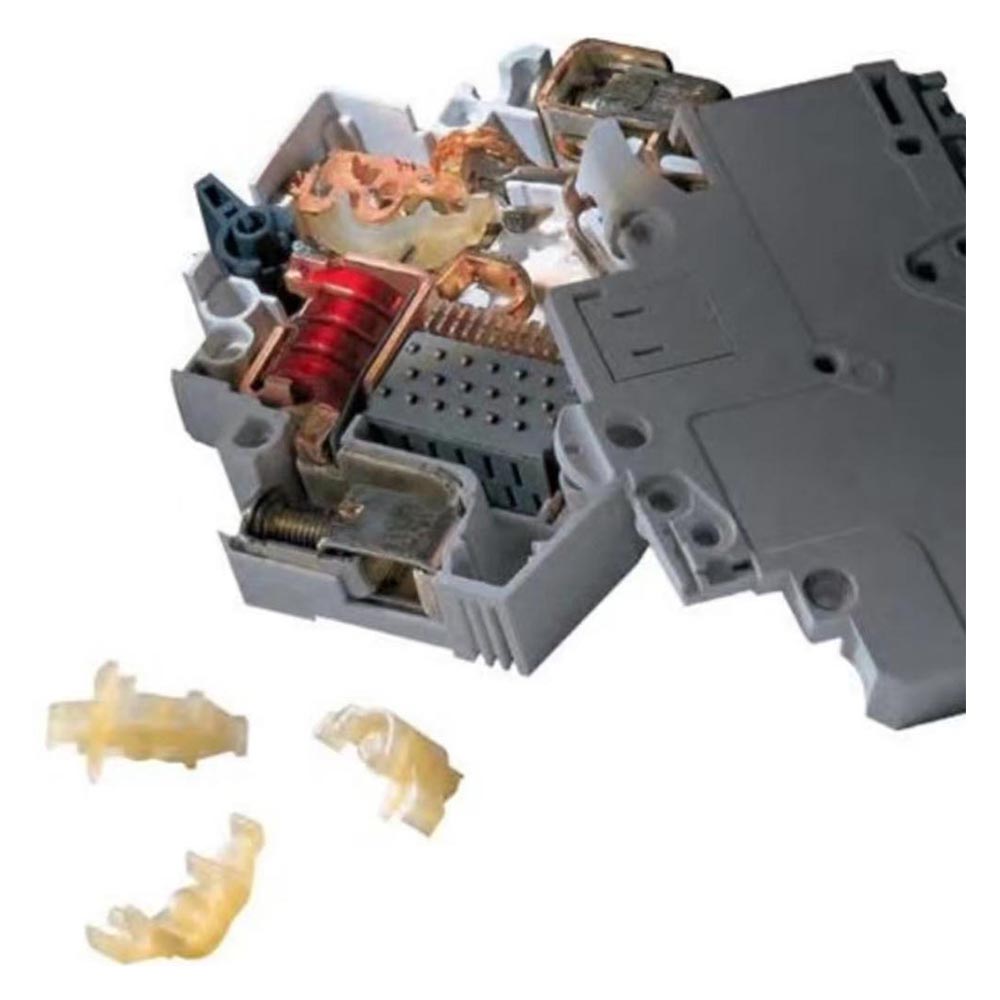

Design: Design the shape and structure of the parts according to the function and purpose of Switch Accessories. Make sure to take into account the properties of PES, such as high temperature stability and chemical stability.

Processing technology: PES can manufacture parts through various processing processes such as injection molding, calendering, and 3D printing. Select appropriate machining processes to ensure parts are manufactured to meet design specifications.

Surface Treatment: Surface treatments such as spraying, plating, or other coatings may be required on parts to improve appearance, wear resistance, or other properties.

Quality Control: Implement quality control steps to ensure manufactured Switch Accessories meet design specifications, checking size, appearance and other key characteristics.

Testing: Conduct necessary tests to ensure that the performance of Switch Accessories meets expected requirements, which may include durability testing, electrical performance testing, etc.

PES was chosen as the material of the tray because PES has excellent mechanical strength and hardness, can provide a stable support structure to prevent damage to the IC chip, and is also resistant to high temperatures and chemicals. Antistatic agents can be added to improve its resistance. Electrostatic properties.

By adding antistatic agents, PES trays can provide good antistatic properties to prevent IC chips from being damaged by electrostatic discharge. Use appropriate processing techniques such as injection molding to manufacture PES antistatic IC chip trays. Ensure that the antistatic properties of PES materials are properly controlled during the manufacturing process.

PES is a relatively lightweight material that facilitates the design of lightweight pallets, easing the burden of handling and storage.