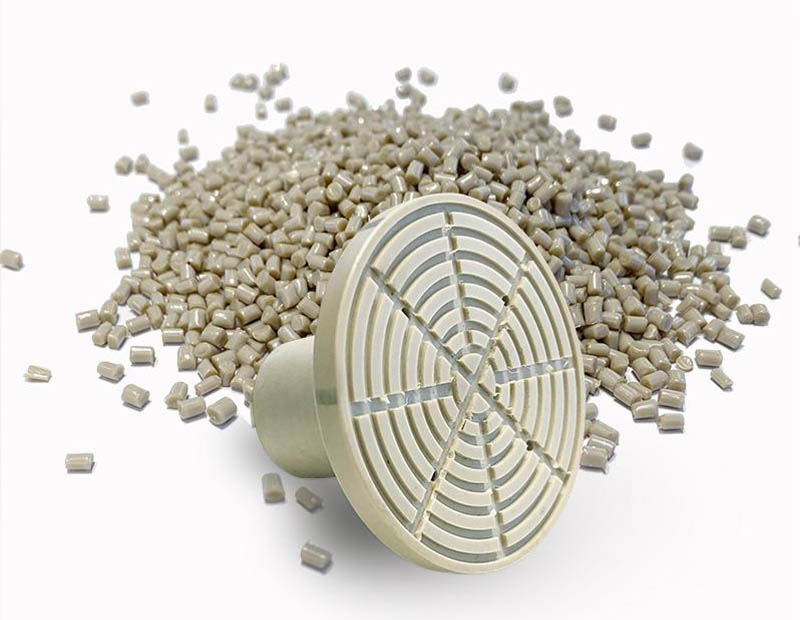

ZTD Polymer offers high-performance Polymer PEEK (Polyether Ether Ketone), including PEEK Sheets, PEEK Rods, and PEEK Tubes, suitable for automotive, electronics, and medical industries. Our polymer PEEK material is renowned for its excellent high-temperature resistance, mechanical strength, and chemical resistance.

ZTD Polymer offers high-performance Polymer PEEK (Polyether Ether Ketone), including PEEK Sheets, PEEK Rods, and PEEK Tubes, suitable for automotive, electronics, and medical industries. Our polymer PEEK material is renowned for its excellent high-temperature resistance, mechanical strength, and chemical resistance.

Polymer PEEK (Polyether Ether Ketone) is a high-performance engineering plastic with the following properties:

High-Temperature Resistance: Can be used continuously in temperatures ranging from -100°C to +260°C, with short-term resistance up to 300°C.

Mechanical Strength: Excellent tensile strength (≥90 MPa) and rigidity, suitable for high-load applications.

Chemical Resistance: Resistant to acids, alkalis, and solvents.

Self-Extinguishing: Complies with UL94 V-0 flame retardant rating.

Radiation Resistance: Resistant to β, γ, X-rays, and microwaves.

Polymer PEEK is widely used in the following industries:

Automotive Industry: High-temperature bearings, seals, and gears.

Electronics Industry: High-frequency circuit boards and insulating components.

Medical Industry: Surgical instruments and implants, meeting biocompatibility requirements.

Aerospace Industry: High-temperature and lightweight components.

Polymer PEEK can be processed using the following methods:

Injection Molding: Suitable for complex-shaped parts, with a molding temperature range of 360°C-400°C.

Extrusion: Used to produce PEEK sheets, rods, and tubes, with an extrusion temperature range of 340°C-380°C.

Machining: Polymer PEEK can be machined through turning, milling, and drilling to create precision components.

What are the applications of Polymer PEEK in the automotive industry?

In the automotive industry, Polymer PEEK is mainly used in components and parts such as engines, transmission systems, chassis systems, braking systems, etc. to improve the performance and safety of automobiles.

What are the applications of Polymer PEEK in the medical industry?

In the medical industry, Polymer PEEK is mainly used in medical equipment, medical devices, artificial bones and other fields to manufacture various medical devices and implants.

What are the applications of Polymer PEEK in the aerospace field?

In the aerospace field, Polymer PEEK is mainly used in structural components, power systems, control systems and other fields of aircraft and spacecraft to improve the performance and reliability of aerospace vehicles.

What is the future development trend of Polymer PEEK?

The future development trends of Polymer PEEK include technological innovation, product upgrades and application expansion, and will be more widely used and developed in automobiles, medical, aerospace and other fields.

Aerospace: Engine parts, structural components, insulators, and wear-resistant sliding parts.

Automotive: Engine covers, gears, pumps, and valve components.

Medical Devices: Surgical implants, instruments, and dental materials.

Electronics & Electrical: Connectors, insulators, and high-temperature electronic components.

Industrial Manufacturing: Pump housings, valve bodies, seals, and high-wear parts.

Polymer PEEK combines high thermal stability, excellent mechanical performance, and chemical resistance to deliver superior performance in the most demanding industrial environments. As a professional PEEK plastic material supplier and manufacturer, we provide various grades of PEEK resin with custom solutions and bulk supply options, committed to supporting your product innovation and enhancing overall performance.

High-Quality Raw Materials: Sourced from internationally renowned suppliers.

Customization Services: Tailored sizes and processing solutions.

Technical Support: Full-process support from material selection to processing.

Fast Delivery: Reliable supply chain for quick response.

Q1: What is Polymer PEEK?

A1: Polymer PEEK (Polyether Ether Ketone) is a high-performance engineering thermoplastic known for its excellent heat resistance, mechanical strength, chemical resistance, and durability in demanding industrial applications.

Q2: What temperature range can PEEK withstand?

A2: PEEK can maintain its mechanical properties at continuous operating temperatures up to 250°C (482°F), making it suitable for high-temperature environments.

Q3: Is PEEK resistant to chemicals?

A3: Yes, PEEK exhibits excellent resistance to a wide range of chemicals including acids, alkalis, organic solvents, and oils.

Q4: Can PEEK be used in medical applications?

A4: Absolutely. PEEK is biocompatible and widely used in medical implants, surgical instruments, and dental devices. It also complies with relevant medical industry standards.

Q5: What processing methods are compatible with PEEK?

A5: PEEK can be processed by injection molding, extrusion, machining, and 3D printing, allowing flexibility in manufacturing complex parts.