PEEK (Polyether Ether Ketone) is a high-performance engineering thermoplastic known for its exceptional mechanical properties, thermal stability, and chemical resistance. As a semi-crystalline polymer, PEEK offers an outstanding balance of strength, heat resistance, and processability, making it a preferred material for demanding applications in various industries, including aerospace, automotive, electronics, and medical.

PEEK plastic is a high-performance thermoplastic polymer made from repeating units of ether and ketone groups in its molecular structure. Known for its outstanding strength, high-temperature resistance, and excellent chemical stability, PEEK belongs to the family of aromatic polyether ketones, which includes similar materials such as PEK (Polyetherketone) and PES (Polyethersulfone).

Due to its remarkable performance in extreme environments, PEEK is used in applications where other materials like metals or standard plastics cannot meet the required performance standards.

High Temperature Resistance: PEEK has a high melting point of 343°C and can continuously operate in temperatures up to 260°C, with short-term resistance up to 300°C.

Excellent Mechanical Strength: Offers superior tensile strength, rigidity, and impact resistance, ideal for high-load and high-stress environments.

Chemical Resistance: Resistant to a wide range of chemicals, including acids, bases, salts, and oils—suitable for harsh working conditions.

Outstanding Wear Resistance: Low friction coefficient and high abrasion resistance make it perfect for high-precision moving parts.

Self-Lubricating Properties: Operates efficiently under dry-running conditions, ideal for bearings, bushings, and sliders.

Flame Retardant: Naturally self-extinguishing with a UL94 V-0 flammability rating—safe and reliable for critical applications.

Excellent Electrical Properties: High insulation resistance, ideal for high-voltage and high-frequency components.

Sterilizable: Withstands repeated autoclaving, making it an ideal material for reusable medical instruments.

| Specification | Description |

|---|---|

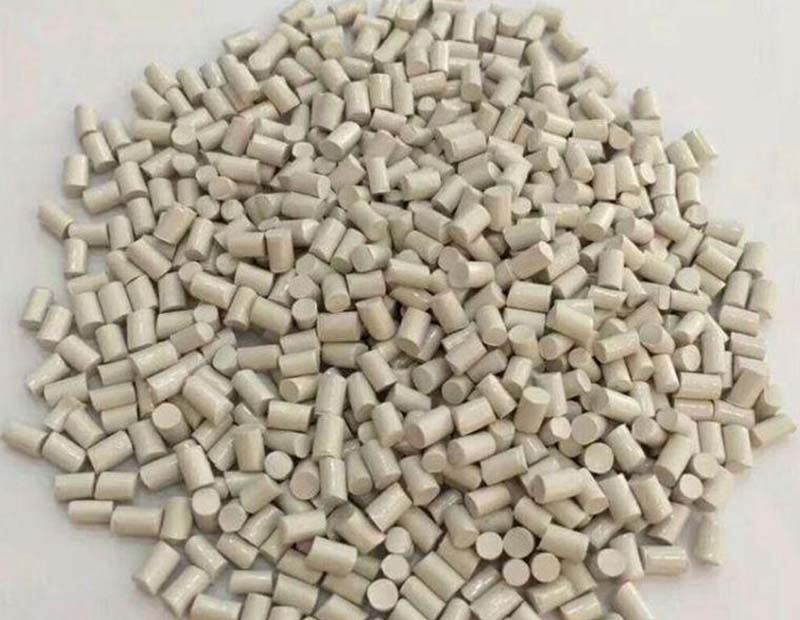

| Material Forms | Rods, Sheets, Films, Granules, Custom Parts |

| Color | Natural (beige/light brown), Customizable |

| Size Range | Available in various dimensions or customized per request |

| Processing Methods | CNC machining, injection molding, extrusion, etc. |

Aerospace: Structural components, seals, insulators, and lightweight parts

Electronics & Semiconductors: Wafer carriers, connectors, insulators, and testing sockets

Automotive: High-temperature engine parts, gears, bushings, and seals

Medical Devices: Surgical instruments, dental tools, orthopedic implants (Medical-grade PEEK)

Chemical Processing: Pumps, valve components, seals, and parts exposed to corrosive media

Food Processing: Heat-resistant contact components meeting food-grade requirements (specific grades)

We offer comprehensive PEEK material solutions, from raw material sourcing to precision-machined parts. Customization based on drawings, samples, and specifications is supported. Multiple forms and flexible delivery options are available to meet your application needs.