As the global focus on sustainability intensifies, the search for materials that not only meet performance standards but also minimize environmental impact has become increasingly critical. Polyether Ether Ketone (PEEK) has emerged as a prominent player in this arena, thanks to its unique properties and potential for recyclability.

1. Understanding PEEK

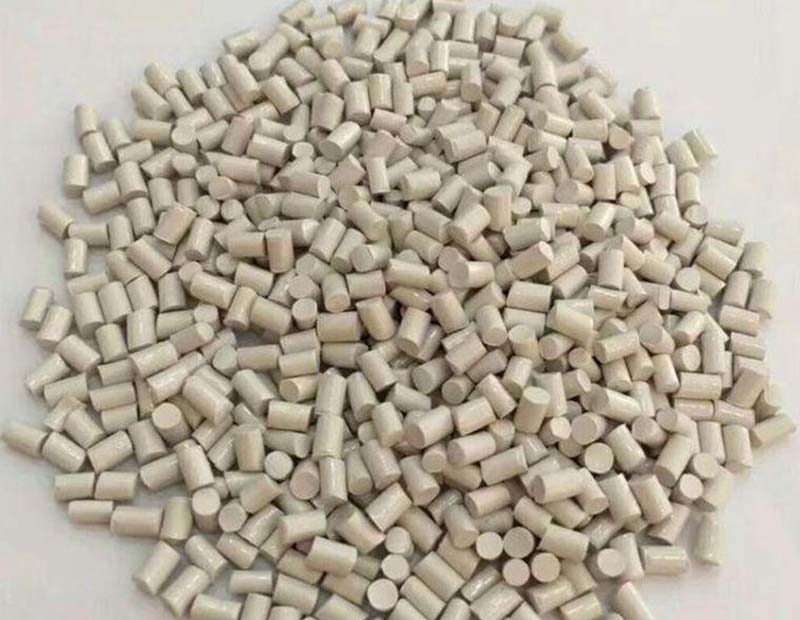

PEEK is a high-performance Engineering Thermoplastic known for its exceptional thermal stability, chemical resistance, and mechanical strength. Commonly used in industries such as aerospace, automotive, and medical, PEEK offers remarkable performance, making it a preferred choice in demanding applications.

2. Environmental Advantages of PEEK

Durability and Longevity: One of the primary environmental benefits of PEEK is its durability. PEEK's high resistance to wear, chemicals, and extreme temperatures means that products made from this material have a long service life. This longevity reduces the frequency of replacements, thereby minimizing waste and resource consumption over time.

Low Emissions During Production: The production of PEEK involves fewer harmful emissions compared to other engineering plastics. As manufacturers strive to optimize their processes, the use of PEEK can contribute to lower environmental footprints during manufacturing.

Reduced Energy Consumption: Due to its excellent mechanical properties, PEEK components often require less energy in application compared to alternatives. For example, PEEK’s lightweight nature can lead to fuel savings in the aerospace and automotive industries, contributing to overall energy efficiency.

3. Recyclability of PEEK

While PEEK is not traditionally associated with recyclability like some common plastics, advancements in recycling technologies are paving the way for its recovery and reuse:

Mechanical Recycling: PEEK can be mechanically recycled, meaning it can be ground down and reprocessed into new materials. This process reduces the need for virgin raw materials and minimizes waste, aligning with circular economy principles.

Chemical Recycling: Research is underway to develop chemical recycling methods for PEEK. This involves breaking down PEEK into its constituent monomers, which can then be repolymerized into new PEEK products. This method offers the potential for complete recovery and minimizes environmental impact.

Design for Recyclability: As awareness of sustainability grows, manufacturers are increasingly adopting design practices that consider the end-of-life recyclability of PEEK products. Designing components that are easier to disassemble and recycle can significantly enhance their environmental benefits.

4. Alignment with Sustainable Development Goals

PEEK’s environmental advantages and potential for recyclability resonate with the broader goals of sustainable development:

Responsible Consumption and Production: By extending the lifecycle of materials and facilitating recycling, PEEK supports responsible consumption patterns. Industries can reduce their reliance on finite resources and minimize waste.

Industry Innovation: The development of new recycling technologies and sustainable practices surrounding PEEK contributes to innovation within the materials sector. This progress aligns with the pursuit of sustainability in manufacturing and product design.

Climate Action: PEEK’s energy-efficient applications in various industries help reduce greenhouse gas emissions, contributing to global climate action efforts.

PEEK presents a compelling case for being both a high-performance material and an environmentally friendly option. Its durability, low emissions during production, and recyclability align well with the principles of sustainability and circular economy. As industries continue to prioritize eco-friendly materials, PEEK stands out as a forward-thinking choice that not only meets demanding technical requirements but also supports a sustainable future. Embracing PEEK can lead to significant environmental benefits, paving the way for a greener tomorrow.