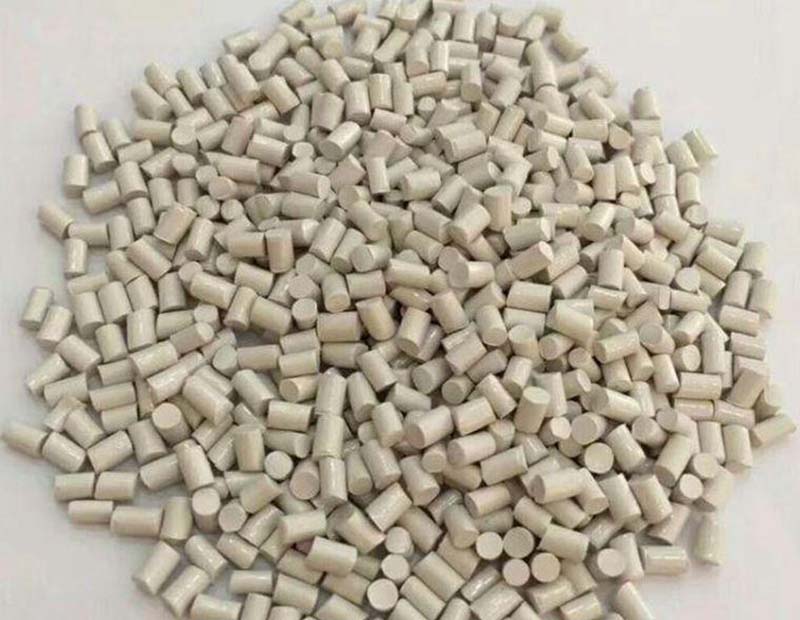

PEEK Plastic (Polyether Ether Ketone) is a premium engineering thermoplastic known for its exceptional combination of mechanical strength, chemical resistance, and high-temperature performance. As one of the most advanced polymers available today, PEEK Material is widely used across aerospace, automotive, medical, electronics, and industrial sectors.

Whether you need high-temperature PEEK Plastic for continuous operation in extreme conditions or chemical-resistant PEEK for exposure to harsh solvents and fluids, this versatile material offers unmatched reliability and durability.

What Is PEEK Polymer?

PEEK Polymer is a semicrystalline thermoplastic characterized by excellent mechanical and thermal properties. It is lightweight yet incredibly strong, making it ideal for applications where both performance and weight reduction are critical. Unlike conventional plastics, PEEK maintains dimensional stability under prolonged exposure to high temperatures, and it resists chemical attack from acids, bases, and organic solvents.

This combination of properties makes PEEK material a preferred choice for engineers designing high-performance components that must endure challenging environments.

Key Features of PEEK Plastic

1. High-Temperature Resistance

High-temperature PEEK plastic can operate continuously at temperatures up to 250°C (482°F) without losing its structural integrity. It also retains mechanical strength under thermal cycling, making it suitable for engine components, industrial machinery, and aerospace applications.

2. Exceptional Chemical Resistance

Chemical-resistant PEEK withstands acids, alkalis, fuels, oils, and organic solvents. Its chemical inertness ensures reliability in aggressive environments such as chemical processing plants, laboratory equipment, and fluid-handling systems.

3. Excellent Mechanical Strength

PEEK Plastic provides:

High tensile strength and stiffness

Excellent impact and wear resistance

Outstanding fatigue resistance for long-term durability

4. Lightweight and Processable

Despite its strength, PEEK is lightweight and can be machined, molded, or extruded into rods, sheets, tubes, or custom parts, making it highly versatile for engineering applications.

5. Electrical and Thermal Insulation

PEEK Plastic is an excellent insulator for both electricity and heat, making it suitable for high-performance electronic and electrical components.

Applications of PEEK Material

Aerospace & Aviation

Engine components

Structural parts

High-temperature insulation

Automotive Industry

Turbocharger components

Bearings and seals

Fuel system parts

Medical Devices

Surgical instruments

Autoclavable components

Implantable devices

Electronics & Electrical Systems

Insulating parts

Connectors

Circuit board components

Industrial Equipment

Pump and valve components

Chemical processing parts

Wear-resistant machinery parts

Advantages of Using PEEK Polymer

Excellent high-temperature performance

Superior chemical and solvent resistance

Exceptional mechanical strength and durability

Lightweight and machinable

Long service life in demanding environments

Suitable for a wide range of industrial, medical, and engineering applications

PEEK Plastic and PEEK Polymer are high-performance materials that combine strength, chemical resistance, and thermal stability in one versatile solution. Whether your project requires high-temperature PEEK plastic or chemical-resistant PEEK, this advanced engineering material offers long-term reliability, precision, and efficiency for demanding applications.